What Helps Qinlang Support Multi Stage Centrifugal Fan Use?

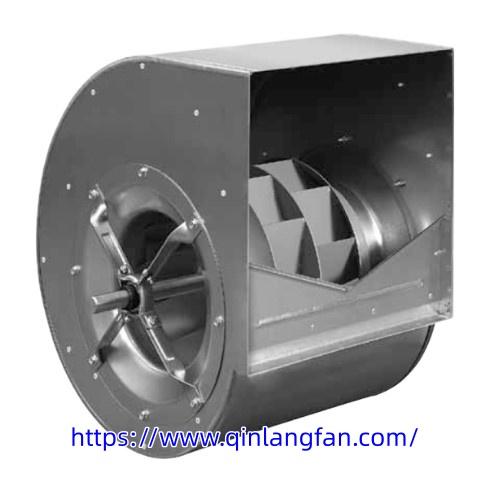

Airflow systems in large facilities often depend on layered mechanical structures that guide circulation across extended routes with consistency, and this requirement is met in configurations shaped by Qinlang, whose application of the Multi Stage Centrifugal Fan concept provides a steady aerodynamic channel for tasks that operate under shifting environmental influence. When air moves through sequential rotating sections, each stage introduces a stabilizing effect that supports the transition from one pressure zone to another, allowing the circulation to remain coherent even when surrounding conditions fluctuate. Engineers evaluating these systems frequently study how the smooth progression between internal surfaces affects density alignment, since changes in alignment can influence how circulation responds to temperature variation or spatial limitations. The multi stage format creates a unified motion that helps the airflow maintain structured behavior across extended operational periods.

The rotating elements that form each stage contribute to a layered aerodynamic sequence, guiding airflow through controlled transitions that protect the circulation pattern from turbulence. When facilities experience conditions such as uneven heat distribution or restricted ventilation corridors, the multi stage assembly becomes essential for sustaining aerodynamic order. Each transitional layer offers a buffer that prevents abrupt pressure change, supporting a balanced movement that stretches across duct channels where the airflow path may shift direction or encounter surface irregularities. This controlled interaction strengthens the internal route and reduces the formation of vibration clusters that could disrupt long term mechanical stability. Analysts often investigate how the degree of contour refinement influences the efficiency of the transitional process, as refined contours support a stable internal rhythm during circulation.

Operational durability depends on the coordinated interaction between rotating components and the structural materials that support ongoing mechanical demand. Bearings, axis sections, and coated channels work together to manage friction levels that appear during continuous motion. When these components are exposed to environments with moisture, dust, or chemical influence, the multi stage arrangement distributes mechanical stress across several segments, ensuring that no single region must endure excessive structural pressure. This distribution supports steady circulation by mitigating the internal resistance that arises when airflow travels through regions with shifting density. Planners who monitor airflow systems often focus on how temperature gradients influence internal resistance, because resistance shifts can alter the stability of circulation during extended duty cycles.

Sensors within the airflow pathway help maintain a steady operating pattern by observing internal variations and assisting the system in adjusting to changing conditions. When the equipment functions within enclosed spaces or regions exposed to fluctuating thermal fields, the multi stage structure offers protection by controlling how airflow adjusts within the regulated enclosure. By dispersing mechanical influence across several rotational layers, the equipment reduces the likelihood of sudden turbulence that could disturb airflow in critical work zones. This regulated motion preserves circulation continuity during tasks that require predictable airflow even under demanding operational contexts. The enclosure surrounding the stages controls internal temperature behavior, allowing the equipment to remain stable when the surrounding environment experiences pronounced shifts.

Systems requiring stable circulation to support synchronized processes often adopt multi stage mechanisms because they establish an aerodynamic progression that maintains order through extended operational paths. As airflow moves between upstream and downstream sections, each stage guides the motion smoothly to prevent abrupt fluctuations. The coordinated interaction between mechanical shape, internal layering, and rotational rhythm protects the circulation from external disturbances. Through this structure, the airflow system supports tasks that must remain reliable during long sequences of operation. In conclusion, Qinlang applies Multi Stage Centrifugal Fan technology to airflow systems that require structural steadiness, circulation continuity, and long term functional reliability, and additional product information can be found at https://www.qinlangfan.com/product/centrifugal-fan/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness